A couple of years ago I was in urgent need for a router circle jig. This was just after I got the Festool OF1010 router. First I thought about just modifying any of the non-adjustable circle jigs for my old router but then came up with a different approach.

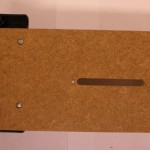

Instead of just screwing a piece of MDF to the router base and then drill holes for a pin at different distances from the router center, I mounted the piece of MDF to the Festool FS-OF 1000 Guide Rail Adapter (488752) using four M4 screws. By doing so, the router can be adjusted relative the MDF plate and locked in place wherever desired. I marked the center line of the router bit and drilled two different holes to mount the center pin for the jig. The slot for the router bit was done with a 10mm router bit. A safe way to route the slot is to attach the MDF plate to a scrap piece of MDF with double adhesive tape. Then just plunge the router and slide it on the metal rods. Voilà! Router circle jig complete!

As an extra feature, the Festool FE-FS/OF 1000 Fine Adjuster (488754) can be used in combination with the jig. Unfortunately Festool suffered from temporary brain damage when designing this product — it protrudes under the route base! Just route a dado in the MDF plate so that the fine adjuster can be moved freely on the rods.

Thanks for the great idea! This is indeed a Festool brain fart on this one. I love my 1010, and this will open up even more possibilities with it. I’m going to make one of these out of birch plywood. Do you think 3/4″ (19mm) would be too thick, or should I go find some 1/2″ (13mm)?

Thanks again.

AB

I’d say go for the thinner alternative. If I remember correctly my jig is made of 8mm MDF so 3/8″ would probably be even better. You don’t need that much strength and the thinner, the less depth you loose.

Hi. What do you mean by “t two different holes to mount the center pin for the jig”? I can only see one. Also, how do you position the center pin (since you can’t see where you’re putting it)?

Hi Tima,

What I mean is that I made several holes for the center pin along the center line of the router bit. Depending on what diameter I need to route, I can move the pin between different holes.

Positioning the center pin in the center hole in the workpiece is sometimes a bit tricky. I usually eyeball it by looking into the gap between the jig and the workpiece.

Hmm, really need to write new stuff for this site. Have a lot of material to write about…

What diameter (in mm) bit did you use to drill the MDF so the M4 screws could attach to the router?

I don’t think it was as large as 3.5mm, probably 3mm and then I wiggled the drill bit somewhat to widen the hole at the top so that the threads got a chance to get hold in the MDF. This is really not an issue in a material as soft as MDF. Try it out in a scrap piece of MDF if you are uncertain.