Have you ever been in the situation where you needed a lathe to reduce the diameter of something? No? Well, I have. Fortunately I own a pretty good old drill press that can be used as a poor man’s lathe in this kind of situations!

For exampel, I needed a new tip to my dial indicator. The new tip needed to be flat at the bottom, which is useful when the indicator is used to adjust the knives on a jointer. What I did was to glue a small brass disc to a M2,5 screw using epoxy. The screw then fits in the dial indicator. The problem was that my brass disc wasn’t equally thick, neither was it centered on the screw during the glue-up. Two things that easily would be fixed on a small lathe.

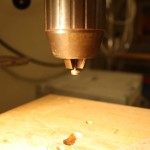

But the drill press? Well, just put the screw in the chuck, put a fine file on the table of the drill press and press the screw against it with the rotation turned on. This results in a flat screw head/disc perpendicular to the screw. Great!

The off-center glued disc was fixed using the very same file and a small piece of wood acting as a support for the file. Just push the file gently against the screw and the problem is solved.

Using the drill press in this way can solve other problems too. I have successfully used it to reduce the diameter of both metal and wood rods and to remove paint from old screws that couldn’t be replaced.